Key Takeaways

- Pogo pins are precision spring-loaded connectors that provide reliable and repeatable electrical connections, commonly used in smartphones, wearables, and test equipment.

- Their compact design supports device miniaturization and enables high-density configurations ideal for modern electronics.

- Key components include a plunger, barrel, and spring, which work together to ensure stable, low-resistance contact over thousands of cycles.

- Pogo pins offer advantages such as vibration resistance, rapid assembly, minimal maintenance, and strong resistance to corrosion due to gold plating.

- Important considerations when choosing pogo pins include contact material, spring force, plating thickness, size, current rating, mounting options, and environmental resistance.

- Customizable features from manufacturers like Promax allow for tailored solutions to meet rigorous requirements in medical, aerospace, and advanced consumer electronics.

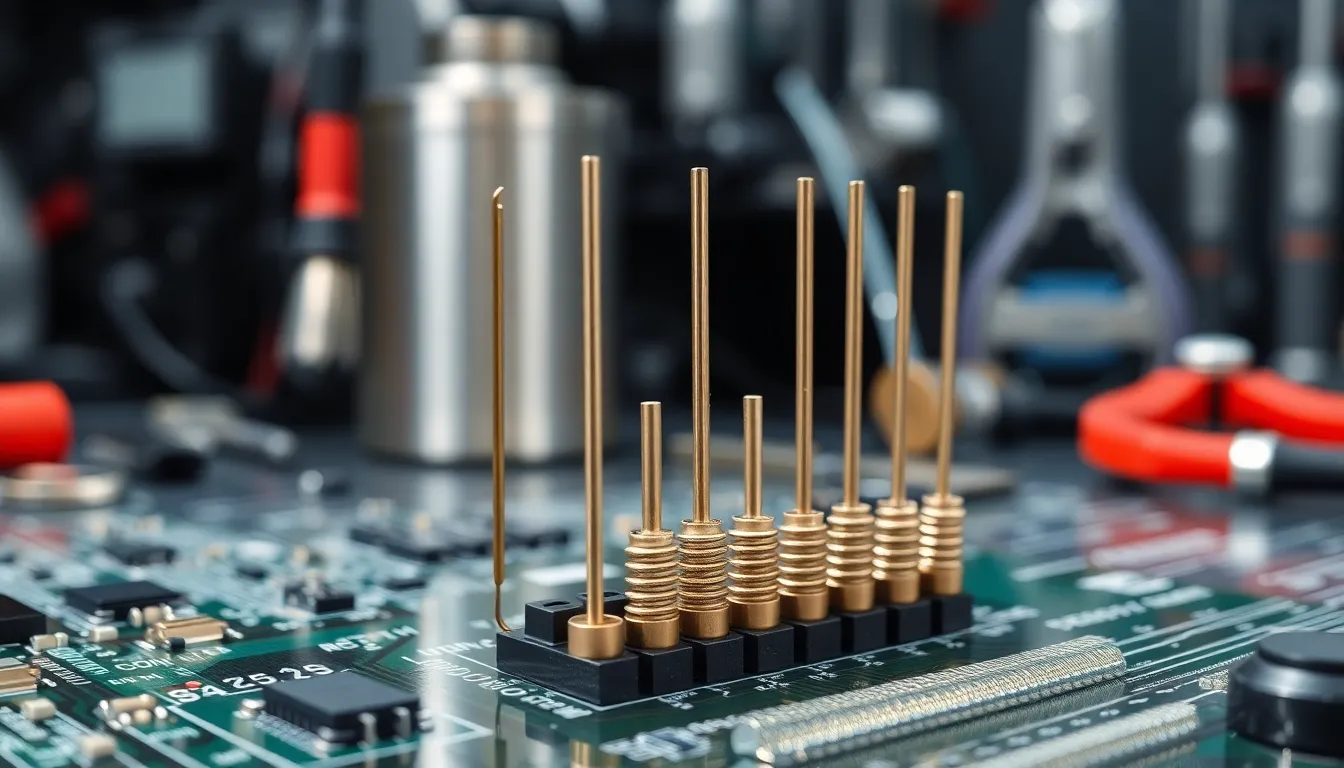

Pogo pins are precision spring-loaded connectors that create reliable electrical connections in modern electronics, from smartphones and wearables to test equipment. These compact components feature a plunger, barrel, and spring design that supports device miniaturisation whilst ensuring stable, low-resistance contact over thousands of cycles. Leading pogo pin manufacturer companies like Promax offer customisable solutions with gold plating and vibration resistance for demanding applications in medical, aerospace, and consumer electronics sectors.

What Is Pogo Pin?

Pogo pin denotes a precision spring-loaded connector used to create secure and repeatable electrical contacts between circuit boards or modules. Pogo pins contain a barrel, a plunger, and a compressed spring that maintains constant pressure against the mating surface, delivering stable connection for signals or power transfer. Electronics such as smartphones, wearables, and medical probes routinely integrate pogo pins for contacts that endure frequent mating cycles without mechanical fatigue. The compact structure, often less than 2 mm in diameter, supports device miniaturization and rapid assembly.

Promax in China engineers pogo pins using high-conductivity materials, like brass and beryllium copper, with surface coatings like gold above 30 μin for low-resistance contact. Inspection covers force, electrical resistance, and life cycle tests up to 100,000 cycles, essential for aerospace and medical device specifications. Promax manufactures single-pin and multi-pin arrays, with pitches starting at 0.4 mm, for test fixtures, charging cradles, and magnetic connectors. Customization options include waterproof sealing, SMD mounting, and high-current capability up to 10A per pin. These features position Promax pogo pins as reliable solutions in high-reliability electronic connectors.

Key Components of Pogo Pins

Pogo pins use three precision components to maintain stable electrical contact under repeated compression. These components—plunger, barrel, and spring—work together to deliver durability and conductivity in high-reliability applications.

Plunger

Plunger forms the contact interface in a pogo pin, moving vertically to make and break electrical connection under applied force. Most plungers use gold-plated brass or beryllium copper for low contact resistance and long service life. Promax polishes and plates the plungers in-house, achieving surface finishes under 0.2 μm Ra, which supports low wear over thousands of cycles. Plunger tip geometry—flat, concave, or dome—matches application needs like test points or charging pads. Dimensional tolerances fall within ±0.01 mm to ensure consistent mating performance in compact assemblies.

Barrel

Barrel houses the spring and guides plunger motion, serving as the fixed anchor in the pogo pin structure. Designers specify barrels with nickel, copper, or steel cores, using gold or nickel plating for corrosion resistance. Promax constructs barrels using deep-drawing or precision turning, holding tolerances to ±0.015 mm for secure alignment. Barrel length, inside diameter, and wall thickness affect spring compression travel and current capacity—often supporting ratings up to 5 A in Promax’s high-current pogo pin lines for medical and charging contacts.

Spring

Spring delivers the contact force that pushes the plunger against a mating pad, establishing a reliable connection. Springs use stainless steel or high-strength copper alloys, finished to resist fatigue and environmental stress. Promax engineers select wire diameters and coil turns to control electrical and mechanical performance, typically providing forces from 50 to 250 grams. Springs complete 10,000 to 100,000 compression cycles without loss of resilience, meeting durability standards for smartphones, industrial testers, and aerospace system connectors.

How Pogo Pins Work

Pogo pins work by using a spring-loaded mechanism that maintains consistent contact between electronic components. The plunger extends from the barrel and makes direct electrical contact with the counterpart pad or trace. During engagement, the internal spring compresses, ensuring that the plunger remains pressed against the contact surface. This action maintains a stable and low-resistance connection even under vibration or movement.

Engineers frequently specify pogo pins for test fixtures, charging docks, and modular assemblies because these connectors allow rapid and repeatable mating cycles. Devices like wearables, industrial probes, and handheld terminals use pogo pins for data transfer or power delivery, relying on consistent spring pressure for signal reliability.

Promax in China manufactures pogo pins with precisely controlled spring force, plunger length, and plating thickness for optimized performance in high-cycle and high-current applications. Their production lines use gold plating on contact surfaces to resist corrosion and reduce contact resistance in demanding environments, such as medical sensors or aerospace systems. Assembly involves automated insertion processes that guarantee uniform compression and alignment, ensuring connector longevity and electrical stability for mission-critical devices.

Common Applications of Pogo Pins

Pogo pins support efficient electrical connections in compact designs. Engineers specify them where high reliability, quick testing, or modular connections are required.

Electronics and Consumer Devices

Pogo pins connect battery packs, circuit boards, and charging docks in smartphones, tablets, and true wireless stereo (TWS) earbuds. Devices use spring-loaded connectors for fast charging, firmware updating, and diagnostic testing. Smartwatches, hearing aids, and fitness trackers use pogo pins to enable contact-based charging cradles and secure signal transfer in small dimensions. Promax manufactures high-precision pogo pins with gold plating and tight dimensional tolerances for these compact electronics, ensuring consistent performance over thousands of mating cycles.

Industrial and Automotive Uses

Test fixtures, printed circuit board (PCB) programming units, and automated test equipment (ATE) in industrial production lines use pogo pins for repeatable connections during quality checks and programming. Automotive manufacturers rely on spring-loaded connectors for diagnostic ports, sensor modules, and control units, where vibration resistance and long cycle life are critical. Promax engineers pogo pins with high spring force, corrosion-resistant platings, and reinforced housings to maintain performance in harsh factory and automotive conditions. Custom design and assembly options allow integration into robotic end effectors and sensor interfaces, supporting flexible manufacturing and vehicle electronics testing.

Advantages of Using Pogo Pins

Pogo pins deliver consistent, low-resistance electrical connections even after 10,000+ mating cycles. Their spring-loaded mechanism absorbs vibration and aligns contact surfaces, which prevents intermittent connections in smartphones and PCB test fixtures.

Engineers reduce assembly time and improve efficiency using pogo pins in modular charging docks and quick-connect test equipment. No soldering or special connectors are needed, which streamlines integration for wearables, medical probes, and portable consumer devices.

Manufacturers, including Promax in China, produce pogo pins with gold plating, high-conductivity copper alloys, and tight diameter tolerances. These construction choices provide strong resistance to corrosion and maintain stable electrical performance under humidity, high current, and thermal cycling.

Designers select pogo pins for their compact barrel sizes, which allow tight placement on miniature boards and flexible configurations. Custom pogo pin assemblies support high-density applications like TWS earbuds and implantable medical sensors.

Promax offers extensive pogo pin customization, delivering unique pin lengths, spring forces, and plating materials for aerospace systems and medical diagnostics. Reliable delivery and strict in-house testing ensure every batch meets international electronic connector quality standards.

Factors to Consider When Choosing Pogo Pins

Contact material affects pogo pin conductivity and durability. Gold-plated brass or beryllium copper enables low contact resistance, higher wear resistance, and reduces signal loss in high-frequency devices like smartphones and medical probes.

Spring force determines mating stability and cycle life. Higher spring force suits automotive testing and industrial applications exposed to vibration. Lower force fits consumer devices such as TWS earbuds, where user comfort and minimal insertion effort matter.

Plating thickness impacts corrosion resistance and wear protection. Gold plating above 1.5 µm resists oxidation in harsh environments, while thinner coatings suffice for controlled environments like PCB fixture labs.

Barrel and plunger size defines fit in compact assemblies. Smaller diameters are ideal for dense circuit boards in wearables. Larger diameters accommodate higher current in battery charging modules and power tools.

Electrical current rating matches circuit requirements. Higher current ratings (3A or above) are essential for charging docks and industrial testers. Lower ratings apply to data transfer-only circuits in compact devices.

Mounting options influence ease of assembly and reliability. Surface-mount, through-hole, and custom housings fit different designs. Promax provides all mounting styles and can customize assemblies for highly integrated electronics.

Environmental resistance matters for longevity in outdoor or automotive roles. Pogo pin models with sealed construction, corrosion-resistant platings, and robust springs from Promax function reliably under temperature, humidity, or chemical exposure.

Customization capabilities at Promax enable client-specific solutions. Engineers specify pin length, tip shape, and spring force, and Promax manufactures to exact tolerances for aerospace, medical device, and consumer electronics use cases.

About Promax Pogo Pin

Promax Pogo Pin specializes in manufacturing high-quality pogo pins, spring-loaded connectors, and magnetic connectors for consumer electronics, aerospace, and medical industries. With over 15 years of expertise, they provide customizable solutions, competitive pricing, and internationally certified quality standards. Whether it’s a standard connector or a custom design, they are equipped to deliver precision-engineered solutions for diverse applications.

Contact:

Gavin Yi, Director

Phone: (765) 705-7361

Email: [email protected]

Website: promaxpogopin.com

Location: 480 Jackson St, Gary, IN 46402, USA

Frequently Asked Questions

What is a pogo pin?

A pogo pin is a spring-loaded electrical connector used to make secure and reliable contact between two electronic components. It consists of a barrel, plunger, and spring, delivering stable connections even after many cycles of use.

Where are pogo pins commonly used?

Pogo pins are widely used in smartphones, wearables, medical devices, charging docks, industrial testers, and automotive electronics for applications like charging, data transfer, diagnostic testing, and modular assembly.

How do pogo pins work?

Pogo pins use a spring-loaded plunger mechanism to maintain steady electrical contact under compression. This design ensures a consistent, low-resistance connection, even during frequent use or vibration.

Why are pogo pins important in electronics?

Pogo pins provide quick, reliable, and repeatable connections without soldering, simplifying assembly and testing processes. Their durability and compact size make them essential for modern electronic device designs.

What materials are used to make pogo pins?

Common materials include gold-plated brass or beryllium copper for the plunger, nickel or copper for the barrel, and stainless steel or copper alloys for the spring, ensuring high conductivity, durability, and corrosion resistance.

What are the benefits of using pogo pins?

Pogo pins offer consistent performance over many cycles, absorb vibrations, reduce assembly time, support compact designs, and ensure strong electrical connections, making them ideal for high-reliability applications.

Can pogo pins handle high currents?

Yes, pogo pins can be engineered for high current capacity by adjusting design parameters like plunger size, spring force, and plating thickness. Manufacturers like Promax provide customized solutions for demanding applications.

How long do pogo pins last?

High-quality pogo pins can withstand 10,000 or more mating cycles while maintaining stable electrical contact. Their spring mechanism and durable materials contribute to a long operational life.

What should I consider when choosing a pogo pin?

Key factors include contact material, spring force, plating thickness, barrel and plunger size, current rating, mounting method, and environmental resistance. These factors affect durability and performance in your specific application.

Can pogo pins be customized?

Yes, manufacturers like Promax offer customization options for pogo pins, including length, tip shape, spring force, plating, and mounting style to meet specific design and performance requirements.